Transversal Textiles

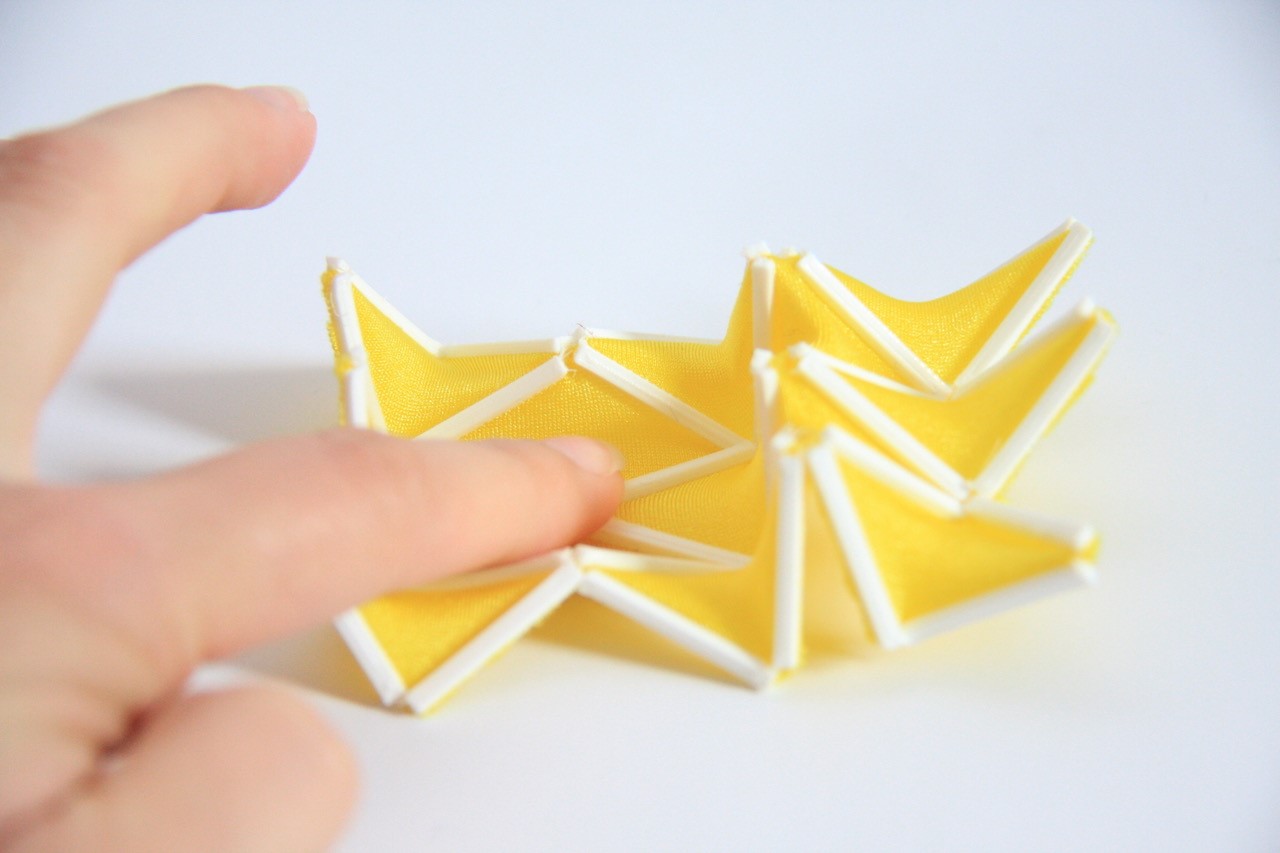

by: Hannah KochIf 3D printing is applied to a pre-stretched textile, textile products can be produced that change their form and function over time – so-called 4D textiles. The change is achieved by a complex interaction between hybrid materials and the influence of an external stimulus. The advantages of textiles as carrier materials are the textile’s ability to store energy and the possibility to produce large-area components with local functionalities.

4D-textiles can be placed in the broader research field of 4D printing. In 4D printing, materials are printed in 3D, which, after the manufacturing process, have variable properties over time in terms of form and function. Researchers in 4D printing are aiming for shape changing, self forming, self healing and robotic materials. Most of these materials are still expensive and difficult to process today.

Due to the complex material behavior designing with these materials is still only available to a few. Additionally, new projects or application designs start form a white piece of paper usually. Most of the learning process is repeated for every project.

With this research project modularization is used as a technique to break down the material in accessible modules with mechanically defined properties. The aim of the research is to support an iterative process through understandable modules in which a certain object behavior can be approximated.

Hannah Koch is a textile engineer and user-centered design coach. Her research focusses on shape changing textiles and the role of prototyping in an engineering design process. She is a graduate from RWTH Aachen University and the d.school for Design Thinking at HPI Potsdam. She conducted research in collaboration with the TU Eindhoven, The Netherlands and IDAS, Hongik University in Seoul South Korea. She is currently working as a scientific researcher at RWTH Aachen University.